eSubsea is a supplier of clump weights and design, manufacture and deliver fully certified clumps weights for mooring lines ready for subsea deployment. They are used as mooring of lines and anchor in hard soil conditions where suction anchors are not the best option. Available for rental or sale. All subsea clump weights (CW) are designed, manufactured and tested according to applicable subsea standards such as DNV 2.7-3 and NORSOK R-002/3 and are delivered with a full documentation package including design reports, material and testing certificates. We also do all required geotechnical engineering in addition to concept and feasibility studies and custom design if the requirements are special.

Standard Clump Weights

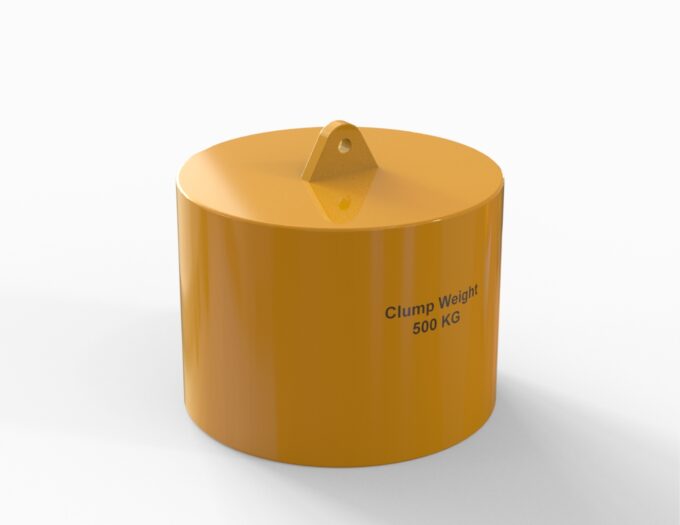

The standard types have submerged weights of 60 kg, 500 kg and 1000 kg with a simple barrel design with a certified and load tested DNV 2.7-3 padeye on the top. The standard clump weight anchor padeyes have shackle interfaces to comply with lifting standards with no installation sea state limitation and actual out of plane loads. These gravity-based mooring anchors are suitable for installation in any water depth. All weights can be delivered with dedicated certified rigging on request.

The subsea anchors (DMAs) are used for wide range of anchoring and mooring applications such as transponder anchor, mooring lines, subsea buoys, subsea protection structure, WLR systems, offshore wind mooring etc.

Custom Subsea Clump Weight Design

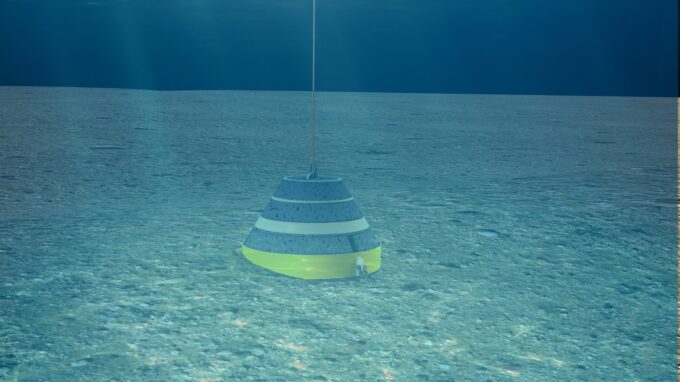

Heavier clump weights can be custom designed to any size or shape based on client requirements and DNV 2.7-3/NORSOK R-002/3 with no limitation on the submerged weights. Normally the Clump Weight design is based on the required vertical holding capacity, but also the lateral sliding capacity can be designed for based on horizontal design loads and the soil conditions. The design can be modular if the vessel lifting capacity is limited.

Certified and tested padeyes or load bars will be included as required. CW are normally used as anchoring or mooring when the soil conditions are hard as is the case for sand, silty sand and hard clay. If the seabed consists of softer clay, a better alternative is to use our suction anchors for seabed support.

The eSubsea clump weight, rental or sale, is for lateral loads are specially designed to provide maximum overturning stability and friction between the seabed and underside of the CW structure. Included in the documentation package will be a geotechnical evaluation with sliding and overturning capacity.

As the structures will most often be subsea for a long time, they are painted with the high standard coating system according to NORSOK M-501 System 7. In addition, they have cathodic protection using sacrificial anodes.

Clump Weights for Any Application

Our clump weights and related subsea products, such as suction anchors, can be used as support, mooring and anchoring for typical applications such as:

- Shallow water or sand/gravel applications

- Drilling rigs and floating offshore platforms

- TLP (Tension Leg Platforms)

- Semi Submersible

- SPAR

- Floating offshore wind foundations

- TLPs

- Semi Subs

- SPARs

- Buoys for electrical cables

- High Buoyancy Applications

- Aquaculture structures

- Fish farms (Salomon, Trout, Cod etc.)

- Fish cages

- Solar energy floating system

- Solar panels farms

- Tidal Power

- Tidal Turbines

- Underwater equipment

- Pipelines

- Buoys

- Wellhead load relief systems

- Underwater monitoring

- Testing equipment

- Ships, docks, berths, pontoons and more

Clump Weight Concept Study

Concept or feasibility studies, including advanced geotechnical evaluations, can be done in order to establish the required submerged weight based on the occurring loads. Based on your input data as loads and soil conditions, the required weight can be established and an outline clump weight design be recommended. The concept study is a cost effective way to quickly establish size, weight, budget cost and delivery schedule for your project. eSubsea, through our company Offshore Wind Design is also developing a new clump weight foundation solution for offshore wind mooring.