eSubsea design and deliver standardised suction anchors, caissons or suction anchors piles, including all engineering, procurement and construction (EPC), fast track and with a low cost. We provide all required, feasibility and concept studies, engineering, structural analysis and design of suction anchors or suction caissons for your project and site specific requirements, including geotechnical evaluations.

The anchor holding capacity (vertical, horizontal or a combination) is typically 10 – 3,000 Tonn (100 kN – 30 MN) per unit and it can be designed for all soil conditions where sufficient penetration by under-pressure is possible, the use of clump weights is another mooring option.

Suction Anchors for Any Applications

Our suction anchors and related subsea products, such as subsea vent hatches, can be used as support, mooring and anchoring for typical applications such as:

- Deepwater applications

- Drilling rigs and floating offshore platforms

- TLP (Tension Leg Platforms)

- Semi Submersible

- SPAR

- Floating offshore wind foundations

- TLPs

- Semi Subs

- SPARs

- Buoys for electrical cables

- High Buoyancy Applications

- Aquaculture structures

- Fish farms (Salomon, Trout, Cod etc.)

- Fish cages

- Solar energy floating system

- Solar panels farms

- Underwater equipment

- Pipelines

- Buoys

- Wellhead load relief systems

- Underwater monitoring

- Testing equipment

- Ships, docks, berths, pontoons and more

eSubsea and our partners can deliver subsea products, concept studies, engineering and design services and offshore and underwater hardware to the North Sea, Gulf of Mexico, Canada, Australia, West of Africa, Brazil and Russia

Design of Suction Anchors

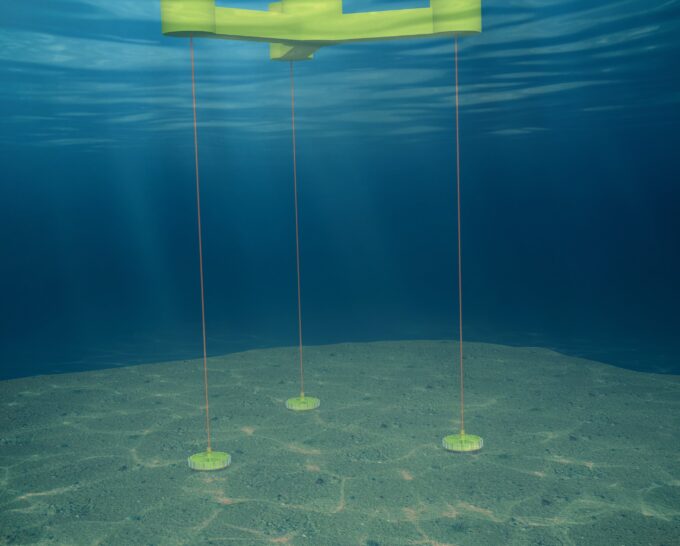

The suction pile or anchors can be designed and calculations done for all seabed conditions and relevant design loads such as installation, fatigue and removal loads from suction/over-pressure and levelling. Suction anchors specially designed for wellhead load relief systems or as mooring for offshore wind foundations can also be provided. These will in addition to normal load conditions also be subjected to fatigue loads which will be a part of the assessment.

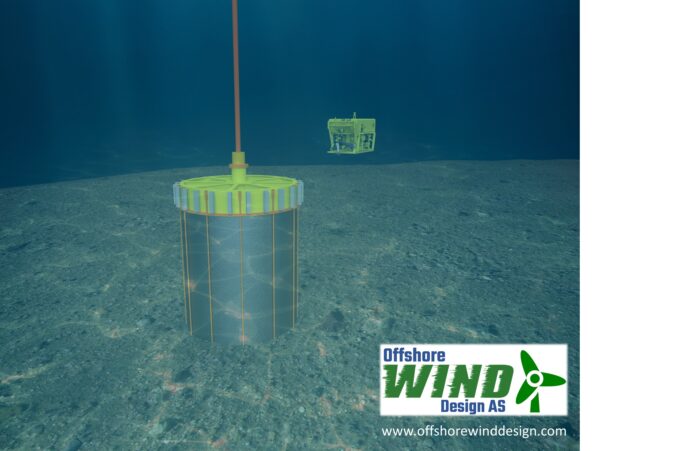

The seabed conditions can be all from soft clay to hard sand and penetration during installation will be done by self-weight and by applying under-pressure using an ROV suction anchor pump after the suction vent hatch has been closed. The geotechnical design including evaluation of stability and holding capacity will be included for anchors in soft clay, hard clay or sand.

Suction Piles and Suction Caissons

The suction anchor also known as suction piles or suction caissons can be used in many applications as shown above which will determine the design and which loads will be applied in the design analysis. It can also be an integrated part of offshore or subsea structures such as a template and manifold foundation of fixed offshore wind turbine foundation. In this case, the bearing capacity and short and long time settlement will be calculated and appropriate designed mase as required.

Anchor Design Codes, Calculations and Loads

When the partly embedded suction anchors piles are used as anchoring foundations for offshore wind foundations and structure, they need to follow the rules, technical requirements and recommendations of DNV-ST-0119 Floating wind turbine structures. The dimensions are found using DNV-RP-E303 Geotechnical design and installation of suction anchors in clay.

Suction anchor calculations and analysis of structural collapse during suction anchor installation and retrieval (skirt buckling analysis) will be performed according to DNVGL recommended practices (DNVGL-RP-C202 and DNVGL-RP-C208). Tolerances and equivalent imperfections according to NORSOK M-101 will be included in the non-linear finite element analysis.

The bearing capacity, penetration resistance and necessary under-pressure will be outlined calculated based a review of soil data available and the requirements for the suction and ROV anchor pump system given accordingly. Pending on the sensibility and importance of the stability and holding capacity, these geotechnical evaluations will in most cases be done by our geotechnical partners.

Suction Anchor Installation

The suction embedded anchor, pile anchor, buckets or caissons can be permanently installed until end of field or temporary for only the duration of the specific operation when they provide seabed support. All load conditions will be included in the engineering and design from support during fabrication on the manufacturing yard to final recovery and removal. The lifting and installation analysis will normally be based on DNVGL-ST-E273 if not specified otherwise by the Client. This is a conservative approach and an option is to perform hydrodynamic analysis using the specific installation vessel data and limiting sea state or significant wave height.

The anchors will have main padeyes and lift points for installation lift but can also have temporary secondary padeyes for transportation and handling. Large suction anchors require significant crane lifting height and it might be more practical to weld on a temporary padeye for horizontal handling. eSubsea can perform these transportation and handling analysis with both structural design and the finite element method if required.

Subsea Anchors Corrosion Protection

The anchors will be protected from corrosion by cathodic protection using sacrificial anodes. The corrosion protection system is based on the surface area and the required time or design life to be under water.

All required documentation such as equipment lists, fabrication drawings, design reports, corrosion protection report, lift test procedures, installation and retrieval procedure are included in the suction anchor engineering package. On delivery, a certificate of conformance will be issued. If the purpose of the suction anchor is temporary, a storage and maintenance manual will be included.

The DeepWater Suction Anchor

eSubsea, through our company Offshore Wind Design AS is developing and patenting a new type of suction anchor foundation that is aimed at the rapidly growing offshore wind market. The new type of anchor will significantly reduce cost directly and also have increased pull out and holding capacity compared to cost. It is particular effective for deepwater TLP applications. This new game changing mooring solution is currently being designed and patented and will be launched as soon as the results are confirmed and patents filed.

Suction Anchor Concept Study

eSubsea with its engineering and geotechnical partners can carry out fast track concept and feasibility studies which include concept evaluation, preliminary suction anchor sizing based on input loads, penetration resistance and required suction, bearing capacity and skirt wall thickness. The concept study is a cost effective way to quickly establish size, weight, budget cost and delivery schedule for your project.