eSubsea can perform PLEM engineering, procurement and construction (EPC) including 3D modelling and drawings, structural analysis, piping analysis, design and verification of PLEM Pipeline End Modules or Pipeline End Manifolds or PLET Pipeline End Terminations or FLET Flowline End Terminations.

EPC of PLEM, PLET and FLET

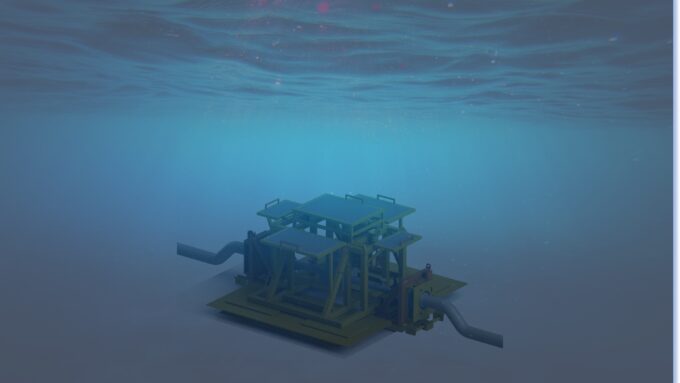

The PLEM, or PLIM if the structure is located in-line the pipeline, is basically a simple subsea manifold at the end of a pipeline where the flow is split into branches and connected to the production or injection wells located on the subsea templates or manifold via flexible or rigid jumper spools.

eSubsea can through our partners also design, fabricate and deliver complementary subsea connection systems for any subsea pipeline or piping module.

eSubsea and our partners can deliver subsea products, concept studies, engineering and design services and offshore and underwater hardware to the North Sea, Gulf of Mexico, Canada, Australia, West of Africa, Brazil and Russia

PLEM Design, Analysis and Engineering

The pipeline end manifolds consist of a suitable foundation structure based on the soil conditions at the site. If the soil is soft clay, mudmats are included to give sufficient bearing capacity. Skirts may also be required for lateral support and sizing will depend on the penetration resistance and self-weight of the structure. The foundation structure also supports the inboard connection system, valves and piping by the HUB porch and valve and pipe supports. Sliding supports are used to minimise loads from thermal expansion of the pipeline.

PLET Structure and Piping Analysis

The static and dynamic structural analysis, including buckling analysis, is performed using structural analysis beam theory software as SAP2000. For local stress and fatigue hotspot analysis, we use Solidworks Simulation or ANSYS. The piping can be analysed using our advanced pipeline analysis software TRIFLEX and to any piping design code, but most common are ASME B31.3 for small bore piping or tubing and B31.8 for large bore piping. Evaluation of flow induced vibrations (FIV) are also part of the piping detail design.

The shallow or deepwater PLEM foundation structures will be designed for all loads as transportation loads, tie-in loads, thermal expansion and flow induced vibrations (FIV). The PLEM protection structure, which could be GRP covers, will also be designed for dropped object loads and fishing gear impact if there is fishing activities in the area. The corrosion design will be by cathodic protection using sacrificial anodes as per DNVGL-RP-B401.

Installation of Pipeline End Manifolds

The offshore installation of PLEM PLET could either be installed with the pipeline or it can be installed separately and later tied-in to the pipeline using subsea tie-in systems. The offshore installation could be first-end or second-end installation. Another option is to install the modules using the drilling riser on a drilling rig. The PLEM structure with the lifting and lay down arrangement is analysed for the installation loads using structural analysis. The lay down method of the pipeline and PLET could be S-lay or J-lay. A hinged lifting yoke is often used to minimise torsion and bending loads during lay-down.

One important aspect of the PLEM structure design is to optimise both the size and weight as this is often critical in particular if the PLET is welded to the pipeline or flowlines on the pipe lay vessel and is overboard with the pipeline.

PLET PLEM Loads and Load Conditions

The PLEM structural analysis will include the following load conditions: Fabrication, testing and handling at fabrication site, transportation, load-out and installation lifting analysis, in-place operation condition including pressure and temperature expansion, pipeline expansion, earth quake, trawling, dropped objects etc.

PLEM PLET Concept Study

eSubsea with its engineering and geotechnical partners can carry out fast track concept and feasibility studies which include concept evaluation, preliminary PLEM PLET design, P&ID, protection structure, connection system, geotechnical, weight and structure and piping sizing based on input data and required codes and standards. The concept study is a cost effective way to quickly establish size, weight, budget cost and delivery schedule for your project.