eSubsea deliver lifting frames and perform fast track engineering, procurement and construction (EPC) including design and verification of all sorts of standard and custom subsea and offshore baskets, subsea baskets and spreader bars.

Design Codes and Standards

The design can be done according to the following codes and standards for design and certification of equipment used for lifting operations subsea, offshore or inshore:

- DNV 2.7-1 Offshore Containers

- DNV 2.7-2 Offshore Service Containers

- DNVGL-ST-E273 Portable Offshore Units (DNV 2.7-3)

- DNVGL-ST-0378 Offshore and Platform Lifting Appliances (formerly DnV 2.22 Lifting Appliances)

- DNVGL-ST-N001 Marine Operations and Marine Warranty

- NORSOK R-002 Lifting Equipment

- NORSOK R-003 Safe Use of Lifting Equipment

DNV Lifting Frames and Subsea Baskets

We recommend to use DNVGL-ST-E273 Portable Units Class with operational class R60 for any lifting device as this will be conservative and satisfy any requirements for most spreader frames, subsea baskets and spreader bars. When it comes to design of lifting equipment, safety must be the number 1 priority. When designing based on custom requirements, a functional specification and a risk assessment will be done to evaluate all aspects with the lifting arrangement.

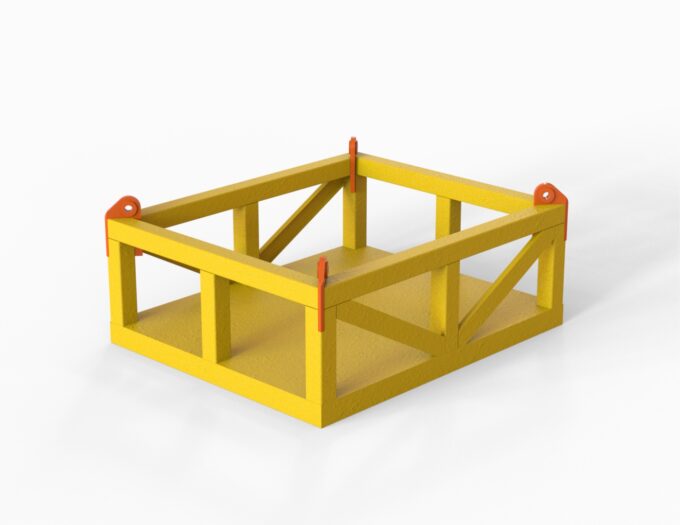

Lifting Frames

Subsea Baskets

The lifting operation using a lifting frame or spreader beam will be designed according to your custom requirement for limited headroom, weight and loads as safe working load (SWL) and maximum breaking load (MBL), number of slings and the location of the padeye and lift points on the object to be lifted. The total lift height or limited headroom may also be limiting and driving the design.

Custom Subsea Basket Design

eSubsea also design custom and standard subsea lifting baskets for handling of equipment from vessel and down to the sea floor. The eSubsea custom designed lift beams can be made in different sizes, load capacities number of attachments points. The types of structures are 4-fixed lift points spreader frame which is ideal for lifting any structure where there are height restrictions. An H-frame can be made for very limited headroom using a single lift point to the crane. Associated wire ropes and certified lift rigging can be provided.